|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Introduction 3.1 As a process, it is fundamental to most herb growing operations. The drying phase is the point at which an otherwise satisfactory crop may be ruined; or its economic value considerably reduced, and yet it is the one process which is most often botched with some quite appalling materials appearing in the market place. Herbs intended as medicinal extracts will almost certainly fail in terms of efficacy and metabolite levels. There are many ways in which plant material may be dried. Small quantities may be prepared for domestic use, from domestic resources. This by time honoured methods, such as bunching and hanging in a warm dark place that has suitable ventilation. The Benefits of Dehydration 3.2

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Figure 3.7A

|

Investigation of plant metabolism has determined that the secondary compounds are produced in extensions, or side streets that branch off the primary metabolic highway. At the junctions, specialised enzymes will sequester an appropriate intermediate molecule for the first step in the production sequence of the required secondary compound. The secondary pathways may loop back to the main highway or proceed to an independent destination. The sheer complexity of such living creatures that are fully conscious has greater implications for our kind than a microbe on Mars. Far flung places, and stars giga lights away, may be our final destination. But if we do not nurture our roots we will never make it For the plants are in us as much as we are in them and by analogy .. a caterpillar on a cabbage. We are just a layer of higher complexity which feeds on them.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

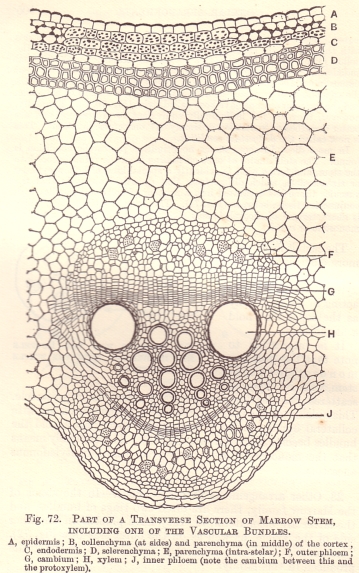

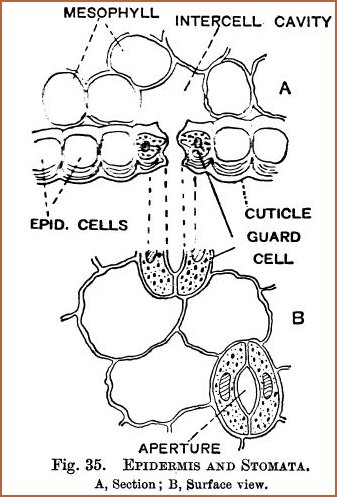

Experiments have shown the metabolic rate of an organism is considerably increased by a rise in the temperature, the rate of many reactions being doubled by a 10�C rise. The evaporation effect of transpiration is cooling therefore the plant is able to modify its internal temperature and reduce its metabolic rate. When the weather is hot and water is short, the plant is able to reduce its rate of transpiration and, within limits, control its metabolic rate. The herbs stem and upper surface of its leaves are covered in much the same way as human skin with thousands of tiny pores called stomata (pl.). the stoma may be opened or closed by 2 sickle shaped guard cells which line the edges of the stoma. Figure 3.8A

The skin or epidermis that surround the stomata secretes a waxy cuticle that inhibits the evaporation of water from the epidermal area of the leaf. For that reason, around 95% of the plants respiration and transpiration is via the stomata, however, in young or partially developed leaves, or for shade loving plants, then the cuticular exchange of gas or vapours could be as high as 50%. The stomata are normally open during daylight hours and closed at night, however they will also close if the plant is in anyway damaged or subjected to environmental stress. Water vapour, on being discharged from the stomata, will linger around the plant and form what is known as the boundary layer. The depth of the boundary layer will vary from specie to specie and will only form in still air, and especially on a moonlit night, a light air movement being sufficient to disperse it. Enzymes the Plant Alchemists 3.9

2. Catalysis only requires minute quantities of enzymes, e.g. 1 enzyme of invertase can catalyse 1,000,000 times its own weight of sugar. Although they facilitate chemical reactions they are not themselves reduced or modified by those reactions. 3. Enzymes are sensitive to temperature (thermolabile), with many being destroyed at temperatures in excess of 70�C. The minimum temperature at which enzyme activity will cease is 0�C or freezing point. The optimum temperature at which enzyme activity is at its greatest is 30�C. The temperatures given are not absolute, for it is not only the degree of temperature that is important but also the duration. As previously stated, metabolism is the sum total of chemical reactions within the plant. Metabolism is of two orders; A. Anabolic; which is a constructive process involving the building up of complex molecules from simpler structures B. Catabolic; which is a destructive process in which complex molecules are broken down into their component parts. Many of the reactions that occur are reversible, i.e., from anabolic to catabolic and back again. In the living plant the reactions are balanced where the rate of reaction in one direction is equal to the rate in the other, thus a state of dynamic balance will exist. Enzymes are highly specialised, in that they can only catalyse one specific type of reaction. Therefore, when a number of enzymes are required for the construction of a compound, they are usually sited next to each other in the same manner as an assembly line unit, each enzyme performing one chemical task before passing it onto the next enzyme until the finished product is ready for the purpose for which it was built. This will continue until the compound has completed its metabolic pathway. Remember that this process of pass the ball occurs at up to 30,000 times a second, and that the enzymes determine the sequence in which they fire. Obviously a disruption of that sequence will prove cataclysmic for the herb being analogous to a multiple high speed motorway smash. Your body contains the same structures found in the green plants. Harvesting shock initiates intense biochemical activity; the dynamic equilibrium of the herb is disrupted as the enzymes commence to fire in random order. Anabolic reactions cease and the catabolic reactions predominate as the herb starts to die. During that process, the important secondary compounds are systematically reduced to primary compounds and from there they decompose to the original elemental state. Therefore, from harvesting onwards the herbs potency, or lack of it, is a function of time, with up to 35% of the herbs pharmacological activity reduced in 12 hours. However, this biochemical activity must be mediated by water. Remove the water and the biochemical activity will cease. Dehydration Time and Temperature 3.10 The water content of the freshly harvested herb must be swiftly and efficiently reduced to 6 or 7% of its total; at which point enzyme activity will cease, the herbal material may then be considered stable. Heat is necessary for the evaporation of water, however the method, the degree and the duration of the heat applied is of prime importance in the production of a quality crop. Many of the herbs secondary compounds are thermolabile when exposed to excessively high temperatures, conversely low temperatures are equally destructive, because the extended drying time promotes excessive enzyme activity. As a general rule drying times in excess of 10 hours are detrimental. The following target times represent operational averages. Actual drying times will depend on the following variables; ambient humidity, dehydrator temperature, specie and the condition of the crop; e.g. due to its increased water content a crop harvested after a period of prolonged or heavy rain will require a longer drying time than one harvested during a dry spell. For similar reasons, a fleshy leaf will require a longer drying period than the average given for herb, with the proviso that all dehydration criteria are met, the target times will produce the best results.

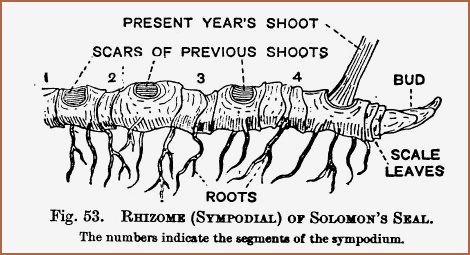

Key to columns 3.11A A. Average water content of the plant material. B. Target times in hours. This will vary either side of the target time. C. Optimum temperatures in �C. D. Air Velocity. This subject will be dealt with elsewhere. Differing species of herb exhibit differing characteristics not only in shape and form, but also in the structural composition of its parts, e.g. soft, hard, fleshy, dense, fibrous, waxy, thick, thin etc; all of which may be considerably modified by geo-climatic factors, which will vary from site to site. Therefore, it is not possible to raise the treatment of each specie to the level of dogma. Good dehydration practice is as much an art as it is a science, and because of the considerable number of variables involved, it has not been possible to reduce the practice to a series of tidy mathematical equations. However some useful charts will be given in the next module. It cannot be stressed enough, fresh herbal material must be allowed to thoroughly wilt so that all of the stomata are open, flaccid and inoperable before being introduced to the dehydration process. The human mind can weigh with finesse, many imponderables, and cope with many contradictions in terms, and then arrive at a workable solution, therein lies the art. The operator of dehydration equipment must temper the science with observation and experience. This is superior to the robotic thermostat controlled operation. Medicinal roots and rhizomes are always in good demand and represent a perennial source of profit for the grower. If a crop is being grown to contract, then the buyer will usually specify processing requirements. For example, if a fermentation process is required then the crop will require a different treatment to that normally applied to root, in that enzyme activity must be encouraged rather than quickly terminated. Two common examples where enzyme activity is necessary are as follows; 1. Gentian Root. (Gentiana spp) Medicinal bitter tonic. 2. Orris Rhizome. (Iris florentina and spp). Cathartic and perfume fixer. If enzyme activity is required then the root or rhizome must be scraped prior to dehydration. Care must be taken to ensure that the material is not scraped beyond the epidermal; layer. The danger being, that because of the low temperature employed, ie 30� C maximum, and the extended drying period, usually 14 to 18 hours; exposed starchy tissue will blacken. Rhizome of Solomon�s Seal. Fig 3.13A As a dehydration problem, case hardening is normally confined to root crops, although it is sometimes a problem with fleshy leaf midribs. The problem arises when moisture is stripped from a surface at a faster rate than the interior of the material can yield it. The outer surface shrinks and shrivels which blocks the internal capillary tubes and traps the remaining moisture. Sometimes that problem is further aggravated by root splitting which is caused by interior expansion and shrinkage. Correctly dried root should snap with a clean fracture, that condition prevails when the root contains around 8-10% moisture. Case hardened material or incompletely dried root tends to be rubbery and may only be broken with difficulty. The tendency is to tear and the material presents a spongy interior.Material in that condition rapidly deteriorates and does not store well. Gradual seepage of the interior moisture starts to occur around the 14th day with the inevitable onset of mildew and mould. When enzyme activity is not required, then the time and temperatures given in Table 3.11A should be followed. On completion of drying, the material should be removed from the dehydrator and allowed to cool down to ambient temperature. This procedure is called �conditioning�. During this period the material will slowly take up moisture from the atmosphere until it reaches its equilibrium point. Equilibrium levels are determined by the type of material, its moisture content and the temperature, humidity and pressure of the ambient air. Providing that the material has been correctly dried, the equilibrium point should fall between 8-12 %. At that stage the material may be considered stable and packed for storage or distribution. Drying the Leaf and Stalk 3.14 Leaf and Stalk Fig 3.14A

The next stage is known as �garbling� which is the trade term for the cleaning and removal of foreign matter, the grower should note, that if excessive garbling is required by a purchaser of dried material, then they will receive a reduced price for their crop. Once cleaned, the material will then undergo a size reduction process, which depending on the material, may need disintegration prior to grinding. To facilitate the size reduction process, and to keep the heat which is generated by it, at non damaging levels, material at equilibrium moisture will need to be conditioned in the reverse order, so that the material once again becomes brittle. The conditioning is carried out at the same temperatures employed in the main dehydration process. Conditioning dryers are usually small and very basic, normally of the �gravity stack� type, which will be discussed later in the text. Unless the grower is involved in manufacturing, these processes will be of no concern. Drying the Flower 3.15

Where petals only are required, no attempt should be made to remove the petals from calyx until the drying process is complete. The petals may then be swiftly and easily removed without damage. In recent years a considerable market has been created in dried flowers for decorative purposes, however a distinction must be made between them and those flowers which are in demand by the drug and cosmetic markets. They are usually of the everlasting type i.e. leathery with a low water content and having very little or no perfume. Such flowers suffer none of the problems that beset the drug and cosmetic varieties. It is usually sufficient to bunch them and hang them in a dark airy place to dry.In regions of high humidity it is possible that water content of the everlasting flowers presents less vapour pressure than that of the ambient air, in which case, it will be necessary to dry them by artificial heat. It will require approximately 10 kg of fresh flowers to produce 1 kg of dried. Because of that, and also the increased cost of processing the grower may expect to receive a corresponding increase in the price received for the crop. Flowers and petals destined for extraction purposes must be of best quality. This means careful attention must be paid to the material throughout the dehydration procedure

Temperature between ambient and 60�C Humidity levels within the dehydrator. As a process, it is of global economic importance, the scientific investigation of which, began a little over 100 years ago. In spite of the vast amount of research undertaken in that time, it remains an experimental science, where many complex phenomena interact and overlap, therefore, drying trials are universally accepted as the most reliable and practical method of determining optimum drying conditions for any given material. Using a standard dehydrator at standard conditions, it would be found that the same type of material taken from different areas would react in a different manner. Dehydration Phenomena 3.17 1. The first phase is the �constant rate�, during which the surface of the material behaves as though it were a free body of water, so that the evaporation rate is constant. 2. The second phase has been labelled the �critical moisture point�. During the constant rate phase the viscosity of the solution within the herbal material is steadily increasing and the constant rate evaporation, which is under way, will start to decrease. The point of decrease is the critical point and marks the change from one rate of evaporation to another. 3. The third and final phase is known as the �falling rate�. The phase is marked by a steady decline in the rate of evaporation until the rate reaches zero, at which point the internal vapour pressure of the herb will be at equilibrium point with the ambient air within the dehydrator. At that stage, the dehydrator is unloaded and the herb left to condition. Each phase will require the dehydrator operator to make adjustments to air speed, temperature and humidity to meet the change in conditions if problems are to be avoided. The operator may detect the phase changes with simple instrumentation comprising of a pair of wet and dry bulb thermometers; the use of which will be covered later in the text. The liquid contained within fresh herbal material is a solution of many different substances e.g. Table 3.17A

The ratio of substances in solution will vary not only by specie but also by harvesting location. The ratio of substances to water, determines the viscosity of the solution, Therefore it is a factor affecting drying rate. As the dehydration process enters the falling rate phase, the viscosity of the solution within the herb is high, and various chemical and physical reactions start to manifest. For example;

Consequently, it becomes increasingly difficult to reduce the final moisture content of the herb. A good operator will use intuition as well as experience when making decisions as to what type of dehydrator climate to employ for a particular type of material, and will need to take into account the following factors; 1. The feel and appearance e.g. rough, matt, smooth, glossy, hairy. 2. It�s weight, density and porosity. 3. The size and shape of the material. 4. It�s estimated water content. 5. It�s estimated shrinkage rate. The operator will have to deal with a wide range of possible species, which when added to the other variables, it will be appreciated that there are a formidable range of factors to be balanced. Apart from a few general pointers it is not possible to be dogmatic and present a table of temperatures, air speeds and humidity levels for any given specie. Climatic and Dehydrator Conditions 3.18 The dehydrator operator must work with the raw climatic conditions as they are found on a daily and seasonal basis, hot, warm, cool, cold and dry, moist or wet. When the raw ambient conditions are introduced to the dehydrator heat plenum, the operator may, by manipulating temperature and air flow, considerably modify the raw air, thus creating a climate suitable for dehydration purposes. Table 3.18A lists some of the probable effects and problems that may occur in the process of manipulating the variables.

Key to table 3.18A A. The operators variable options. B. An increase in dehydrator temperature. C. A decrease in dehydrator temperature. D. An increase in air flow through the dehydrator. E. A decrease in air flow through the dehydrator. F. An increase in dehydrator humidity level. G. A decrease in the dehydrator humidity level. H. Problem area, dew point could be reached. Note to column �H� Dehydration Factors 3.19 Within the ambit of the drying temperatures given in Table 3.11A, and the operators judgment of the material on hand (see section 3.17), the following may be used as a general guide for dehydration conditions during the constant rate phase. The falling rate will require adjustments and the operator is referred to Table 3.18A.

The aforementioned factors are applicable to a forced draught dehydrator. The type of drying technique employed is usually determined by the nature of the material and it�s commercial value. There are many types of apparatus available, many of which are not suitable for the range of applications for which they are advertised. In price, they range from expensive to astronomical. For a modest outlay, the grower may purpose build apparatus to meet specific requirements, however, it will be helpful to have a brief review of current methods. Sun and shade drying 3.20

Generally speaking, consumer awareness of what constitutes good or bad material is low, and when such materials find their way into the market place the herbal industry as a whole, is damaged, the perception being that such poor material is atypical. All reputable processors give such material a wide berth. Microwave Drying 3.21 Microwaves have an affinity for water molecules, when the molecules are encountered in living tissue an intense vibration of the water molecules ensue. During which a very high temperature is generated within the tissue, 300� C being reached within seconds. The water in the herb immediately starts to boil off at high speed from the interior out. The secondary metabolites decompose rendering the herb useless for medicinal purposes, the herb having been cooked rather than dried. Such materials although they may smell correct when removing them from the oven are totally useless within 24 hours, little more than colored garnish. The initial high smell is the smell of the volatiles distilling off at speed. Belt and Flash drying 3.22 Flash dryers are similar to spray dryers in operation, except that the chopped herb is blown into a circular drying chamber via a duct or pipe, which is set at a tangent to the chamber. This creates a vortex effect in the herb as it descends to the bottom of the chamber. Operational temperatures vary from 3 to 400� C. The herb is reduced to 40% moisture at a single pass. The herb is then removed to a belt dryer for �finishing�. The belt dryer is basically a series of staggered moving belts, set one above the other and housed in a rectangular chamber, the speed of the belts is variable. The partially dried herb is introduced at a top end and recovered at the opposite bottom end. The herb is finished at around 130� C for 30-35 minutes. Such methods are used by many American and European herb processors for the drying of such materials as chervil, chives, onion greens and parsley; a bright green colour being retained by the herb. It is claimed that the time exposure to the high flash drying temperatures is so short that �no damage is caused�. A highly debatable point! It should also be noted that the belt dryer temperature is 3 times that temperature recommended for herb. Certainly the cosmetic grading is excellent, but anyone who has purchased such herbs on the basis of its bright colour, knows that the flavour rating leaves much to be desired, it�s main function being that of a coloured garnish. The method, while not quite so violent as micro waving, is totally inappropriate for herbs. Freeze Drying 3.23 Essentially the herb is first blast frozen and then exposed to a high vacuum, so that a water vapour pressure lower than that of the herb is attained. Under those conditions the water will distil, or more accurately, �sublime�, from the herb. The speed of the evaporation maintains the herb at low temperature. The finished product has a paler colour than the flash dried material. It retains its size and shape, however its porosity is magnified and the freeze dried herb is extremely hygroscopic and shatters easily. This increased tendency to absorb moisture means that the herb needs to be stored in hermetically sealed containers. For culinary purposes the freeze dried herb is of excellent flavour. The markets however are very limited due to the high cost of the herb usually 4 to 5 times that of its air dried equivalent. Convection Drying 3.24 The resulting water vapour is then removed by natural, or forced convection of the surrounding air. Given the relative fragility of herb and its compounds, the use of direct radiation or contact plates, would cause unacceptable damage, however, the use of steam pipes would meet all of the relevant criteria, with a bonus of precise temperature control. Unfortunately the capital and maintenance costs are uneconomic for the small scale grower. Solar Drying 3.25 The place of Helio-technology in herbal processing will be further discussed in a later module. Beyond a few pointers it is not intended to belabour the subject, there is a wealth of information contained in many excellent publications held by public libraries or from the internet. After three seasons of practical experimentation (from 1984 to 1987), undertaken in the Auckland region of New Zealand, I was forced to the reluctant conclusion that in temperate or sub-tropical climates, solar energy as a sole heat source is inappropriate for the dehydration of herbal materials, in that it does not meet the critical criteria. The experiments were carried out on Waiheke Island at approximately 36�48S, 175�E, at sea level (101.325 kPa) The seasonal climatic variations, rendered heat gain erratic and unpredictable. Average maximum /minimum temperatures, for the seasons in point, were 18�C and 12�C respectively, a yearly average of 15�C. Humidity levels rose steadily from sunrise until around 2 pm., then declined steadily until sunset. Highest levels were recorded during the winter months often topping 80%. The seasonal average was 71%. Notwithstanding the negatives associated with solar herb drying in temperate or sub-tropical zones, the use of solar energy for herb processing has an important role, its intelligent use not only contributes to a cleaner, safer environment but will also provide a substantial economic gain. Dessicants and Ambient Humidity 3.26 Hygroscopic materials, of which there are many, are commonly called desiccants. Commercially, they are widely used to scrub or clean saturated gas emissions, e.g., oil refineries and sulphur. The process is known as absorption, in that the contaminant is held on the surfaces of the desiccant, therefore, rough porous granules will have greater absorption powers; i.e., they present a greater surface area than that of a smooth surface of similar size. A widely used desiccant for pharmaceutical purposes is calcium chloride (anhydrous) and the process is known as desiccation. The desiccation process is carried out in an airtight container or chamber under reduced pressure. The resulting water vapour from the substance undergoing desiccation is adsorbed and condensed without a change in temperature, this phenomenon is an isothermal condition. It is believed that the condition is not a function of molecular vibration but rather that of atoms changing place. The rate of adsorption is affected by temperature. Adsorption decreases with an increase in temperature. Decreased temperatures will increase adsorption. Under normal atmospheric conditions heat always flows from hot to cold, therefore the desiccant will absorb heat and water vapour until it reaches equilibrium with the atmospheric air, thereafter, the desiccant (which will need to pass around 4000m3 of ambient air to produce 25kg of dried herb), will commence to act as a free water surface. If calcium chloride is being used then it will start to deliquesce and a saturated solution of calcium chloride will start to drip from the filter. This process is evaporation and the heat gain to the solar panel will be lost. The overall effect on the condition of ambient air will be best understood by study of the psychometric chart which is given in a later module. The economic cost of the increased running time for the fan or fans is further compounded by the power increase needed to overcome the static pressure of the desiccant filter. The simple answer to the problem of high ambient humidity is to boost the temperature of the incoming air. The inability to raise the temperature to a sustained viable level is the crux of the problem for stand alone solar air herb drying in humid climates. A primary heat source is required. A solar heated air panel can then be used to mitigate the cost of fuel. Air as Drying Medium 3.27 The drying of herbs in a warm air stream mimics but accelerates the natural process and has many advantages;

� Herbdata NZ Ltd. 2003. Library

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Earth

Air Fire and Water

Earth

Air Fire and Water

It

is also for these reasons that the root must remain whole rather than

chopped or sliced. The fermentation will proceed until the water content of

the root reaches around 8 to10%. When that occurs enzyme activity will

cease. The dehydration process must be closely monitored to ensure that root

splitting or case hardening does not occur.

It

is also for these reasons that the root must remain whole rather than

chopped or sliced. The fermentation will proceed until the water content of

the root reaches around 8 to10%. When that occurs enzyme activity will

cease. The dehydration process must be closely monitored to ensure that root

splitting or case hardening does not occur.

When

correctly dried the leaves should be crisp and the stalks should snap. In

this condition the herb is fragile and prone to damage and leaf shatter. So

handling should be kept to a minimum and the herb treated with care during

the conditioning period. If that procedure is followed, then experience has

demonstrated that moisture determination tests prior to storage are

unnecessary. Moisture determination tests although simple are, for the

purposes of accuracy, usually carried out in a laboratory and could prove

expensive, and in field conditions they are not a practical option.

When

correctly dried the leaves should be crisp and the stalks should snap. In

this condition the herb is fragile and prone to damage and leaf shatter. So

handling should be kept to a minimum and the herb treated with care during

the conditioning period. If that procedure is followed, then experience has

demonstrated that moisture determination tests prior to storage are

unnecessary. Moisture determination tests although simple are, for the

purposes of accuracy, usually carried out in a laboratory and could prove

expensive, and in field conditions they are not a practical option.

Damaged

or discoloured flowers or petals are virtually worthless, with the only use

being for ballast or bulking agents in low grade pot-pourri.

Damaged

or discoloured flowers or petals are virtually worthless, with the only use

being for ballast or bulking agents in low grade pot-pourri.  The

The