Herbs In Africa

Extraction Apparatus.

Part 5

Part~1

Part~2

Part~3

Part~4

Part~6

by

Ivor Hughes

The

procedures and apparatus required for extraction purposes are simple. Skills

required would be carpentry, and light engineering skills, such as metal

cutting, drilling, and welding.

When considering the economics of small scale processing plant, there are

four factors that need to be balanced.

1.

Construction Cost

~ The costs may be reduced by utilizing used

dairy or food processing equipment. The main cost is for welding

services.

2.

Operational Cost ~ Energy use is a prime cost. Unwanted heat loss

will add considerably to energy use, as will bad design. Faulty design

produces increased labor costs, e.g., difficult load/unload

procedures.

3. Maintenance ~ Parts and fittings that are awkward and difficult

to clean will add considerably to labor costs.

4. Durability ~ Fragile parts such as sight glasses should have

adequate protection. Seals and breakable joints that have to be dismantled

should be of good quality. Stopcocks, taps and valves should be corrosion

proof.

Contamination problems may easily arise because of the nature of the

substances involved in the processing, from chemical action of one substance

on another, e.g., heavy metals leached from the equipment are in themselves

toxic contaminants, which may then trigger a further reaction in the

substance being operated on.

Great care should be taken in the selection of materials that will be in

contact with solvents or herb extracts. If using plastics or rubbers, then

ask the supplier for the specifications of use. Do not use glaze ware

unless you know what type of glaze it is.There are also several

physical factors that need to be considered, e.g.,

A.

Strength and Weight ~ Will the equipment be fixed or portable? Will the

equipment be able to withstand any stresses placed upon it?

B. It's

Durability

~ Parts that are in contact with liquids and

vapors must be resistant to corrosion. Metals that are prone to rust should

as far as possible be avoided.

C. Thermal

Expansion and Conductivity ~ When mating materials, which are different,

remember that they will have differing thermal expansion rates. That

will produce stress or fatigue with an increased risk of fracture.

Distillation equipment and condensers should possess good thermal

conductivity.

D.

Cleansing and Sterilizing

~ Smooth polished surfaces will simplify

cleaning and sterilizing and help in the prevention of the formation of heat

resistant films.

Two of the most commonly used materials for plant construction are copper

and stainless steel. If considering copper, then it is most important that

all linings in contact with the herbal materials, liquids or vapors,

must be tin plated. Copper is a heavy metal that can cause liver damage. (hepatoxic).

Stainless steel will meet all criteria. Costs may be kept to a minimum

by purchasing and modifying used vats, fittings and tubing.

Austenitic

Stainless Steels.

When nickel is added to stainless steel in sufficient amounts the

crystal structure changes to "austenite". The basic composition of

austenitic stainless steels is 18% chromium and 8% nickel. Austenitic grades

are the most commonly used stainless steels accounting for more than 70% of

production, type 304 is the most commonly specified grade. A higher grade is

type 316

Basic

properties.

excellent corrosion resistance

excellent weldability (all processes)

excellent formability, fabricability and ductility

excellent cleanability, and hygiene characteristics

good high and excellent low temperature properties

non magnetic (if annealed)

hardenable by cold work only

Percolation is a method of extraction achieved by the downward displacement

of soluble extractive by a suitable solvent through a suitably comminuted

drug plant. The process is a combination of maceration and percolation

and is sometimes referred to as a process of "Macero-Percolation'. Not

all plant drugs are suitable for the process (see Section 11-21). There are

7 distinct operations involved, they are in order of operation;

1.

Comminution.

The principles of size reduction are covered

in section 11-16. Remember if the particles are too fine a solid cake may

occur, this will effect the downward flow of menstruum and will most

certainly lead to the formation of 'dry pockets' within the body of the

material which will escape extraction. It the material is too coarse then

interstices are formed through which there is a speedy percolation of

menstruum which produces an incomplete extraction and will require

excessive volumes of menstruum to exhaust the marc.

1.

Comminution.

The principles of size reduction are covered

in section 11-16. Remember if the particles are too fine a solid cake may

occur, this will effect the downward flow of menstruum and will most

certainly lead to the formation of 'dry pockets' within the body of the

material which will escape extraction. It the material is too coarse then

interstices are formed through which there is a speedy percolation of

menstruum which produces an incomplete extraction and will require

excessive volumes of menstruum to exhaust the marc.

The

Principles of Size Reduction

The methods of size reduction (comminution) and the classification of

particles obtained are covered later in the article. A major factor in

the solubility of a substance is the amount of surface area exposed to

a solvent.

The greater the exposed surface, the faster and more complete is its entry

into solution, e.g.

|

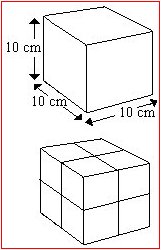

The cube has 6 sides each side is 100 cm2 -: area exposed is 6 x 100 cm2 = 600 cm2. We slice the cube into 8 equal portions. The surface area for each cube is 6x 25 cm2 = 150 cm2 -:- 8x 150 cm2 = 1200 cm2 |

Therefore

we have doubled the surface area.

The degree of comminution required will also depend on the composition of

the crude drug e.g. is it hard or soft ?, is it thick or thin ? If the

drug is leaves or petals then it will be easily penetrated by the solvent,

therefore the degree of comminution need not be great, whereas hard and

woody substances will require a greater reduction in size. Some substances

such as aloes or gum resins need only be crushed, therefore it is a

matter of becoming familiar with the material being operated on. The

following categories will serve as a general guide.

(A) Broken

or Crushed. Gums, resins and inspissated juices. Most seeds and

fruits.

(B) Sliced

or Small Cut. Rinds, skins, pith, stalks.

(C)

Rasped.

This type of size reduction is of dubious value and is only officially used

for quassia which is a hard wood. From personal experience the tedium may be

avoided by pulverizing such substances.

(D)

Powders.

Rhizomes, roots, barks, woods, corms. There are 5 official grades of

powder.

Table

11-16A

| -1 | 18 mesh | Coarse Powder |

| -2 | 25 mesh | Medium Coarse |

| -3 | 45 mesh | Moderately Fine |

| -4 | 80 mesh | Fine Powder |

| -5 | 120 mesh | Very Fine |

Further

details may be found in Section 6-45. For extraction purposes we may ignore

the 80 and 120 mesh with the 25 and 45 mesh being most often used.

The final consideration for the degree of comminution needed is the

menstruum or solvent to be used for the extraction. Remember that our

solvents are water, alcohol or a combination, i.e., dilute alcohol.

The

tissue of crude drugs in the dried state will contain around 4 to 5%

moisture (see Section 4-17) if it has been properly conditioned, therefore

if water or a dilute alcohol is used as the menstruum it will penetrate and

spread rapidly through the plant tissue; whereas strong alcohol i.e.,

50% by volume or over in the initial stages will cause a shrinkage or

hardening of the tissue because the water is pulled to the surface thus

shrinking the interior. This phenomenon may be explained by the fact that

ethanol molecules have a hydrophilic tail.

Apparatus for Size Reduction and Particle Classification.

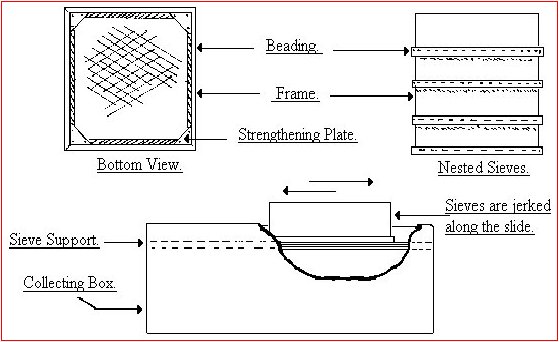

Classification by Sieve.

Classification by sieve, may be used directly for particle reduction if

using whole dried herb. Sieves are further used for size classification of

materials that have been subjected to other means of size reduction.

Size

Reduction.

Small scale

size reduction may be achieved by the use of a mortar or pestle or on a

larger scale, the same method that is used to produce mealie from dried

maize in a village situation.

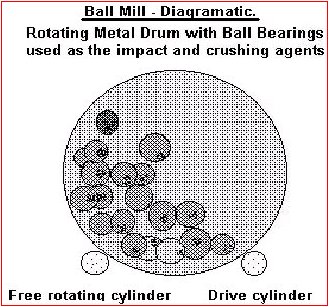

For larger scale work a suitable ball mill may be constructed from scrap

parts. It may be powered by hand, pedal, or other motive force such as a

suitably geared lawn mower engine or the electric motor taken from a

discarded washing machine. The general principle is :

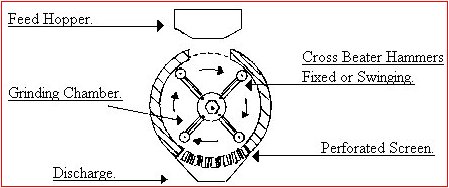

Alternatively an agricultural feed mill will also serve the purpose but it

will require an engine or electric motor to operate the apparatus. Size

reduction is achieved by fixed or swinging beater arms revolving at speed

within a chamber.

The Hammer

Mill.

Small Scale Extraction Apparatus.

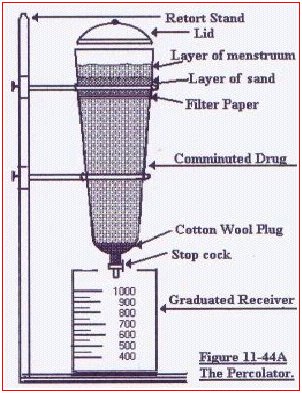

The diagram represents a typical piece of laboratory extraction ware. It will be seen that the principle is simplicity itself. Larger scale apparatus may be constructed from discarded milking equipment. 50 or 100 litre containers would meet the needs of the larger cultivation. It is not necessary for the extractor body to be tapered. However a domed bottom as shown in the diagram would facilitate the efficient extraction of the herbal materia

Choosing an Appropriate Extraction Process.

When considering a crude drug for extraction purposes thought must be given to whether the drug is classified as 'organized' or 'unorganized' . If the drug has no clearly defined cellular construction it is unorganized. The maceration process is the only method suitable for unorganized drugs such as gums, resins, oleo-resins etc. Such materials are unsuitable for percolation because the residues would block the percolation process. The same restriction will also apply to crude organized drugs that produce large amounts of mucilage e.g. flax or psyllium seed. In other cases if a drug for whatever reason cannot be reduced to a powder then it is not suitable for a percolation process. Some drug materials e.g. Garlic and squill are extremely hygroscopic and in the presence of water tend to fuse into lumps which make them unsuitable for the percolation process.

Tinctures from Unorganized Drugs.

Maceration

is the only feasible method of producing a tincture from an unorganized drug

such as gum benzoin or propolis resin. Further information on the

exudates will be found in Sections 9-16, and 9-51 et seq. 9-57.

The marc from the exudates is usually slimy or gummy and may also

consist of various types of debris e.g. insect parts, fragments of

soil or plant parts. The gums are insoluble in alcohol while the resins or

oleo-resins will pass completely into solution. The gum and debris will sink

to the bottom of the maceration vessel. The separation of the

supernatant liquid is usually by simple decantation or if required by

filtration. There is no advantage to be gained by attempting to press the

marc because all of the soluble constituents have entered into

solution.

2.

Imbibition. The word is derived from the Latin meaning

'to drink in'. The comminuted drug thoroughly moistened with a portion of

the menstruum. This is best done in a lidded container of a suitable size.

The moistened drug is allowed to stand for a period of four hours to allow

the drug to imbibe the menstruum and thereby swell to its maximum capacity.

The container used should be large enough to accommodate the expansion of

the drug.

3.

Packing.

On completion of imbibition the drug should be passed through a number 10

sieve (Table 6-45A) to break up any lumps that may have formed. The drug is

then transferred to the percolation vessel in portions. Each portion

should be firmly packed but not so firmly that liquid is forced from

the drug but sufficient to exclude any air pockets.

4. Maceration. Open the stop cock on the bottom of the

percolator and pour in the menstruum in portions and allow to percolate

through the packed drug. If the menstruum drips through the stop cock in

less than 10 minutes, the drug is too loosely packed. If the first

drop takes 25 minutes or more then the drug is too tightly packed. If

all is well, then close the stop cock and pour in sufficient menstruum

to leave a layer 1 or 2 cm deep over the drug. Cover the percolator and

leave to macerate for 48 hours in a warm dark place at a temperature

not exceeding 25�C.

Library

Part~1

Part~2

Part~3

Part~4

Part~6

The Pharmageddon Herbal

The

equivalent of a 3 year certificated course in Western Herbology, Save

yourself thousands.

These articles have been published in

Science In Africa

www.scienceinafrica.co.za

Next in this series:

Extraction Products.

![]()