Sugar (Sucrosum) USD 1926

Compiledby Ivor Hughes

SUCROSE Sucros. [Saccharum U.S.P. IX, Sugar]

"A sugar [C12H22O11] obtained from Saccharum officinarum Linne (Fam. Graminece) and other sources." U. S. "Refined Sugar is a crystallised sugar, C12H22O11, obtained from the juice of the sugar-cane, sugar-beet, and other plants." Br.

Saccharum Purificatum, Br.; Refined Sugar; Cane Sugar. Saccharose; Saccharum Album; Sucre blanc officinal, Fr, Cod.; Sucre de Canne, Sucre de Betterave, Fr.; Saccharum: P. G.; Weisser Zucker; Zucker, Rohrzucker, G; Zucchero, It.: Asucar refinado, Sp.

The sugar cane, Saccharum officinarum, is a perennial herb possessing a jointed, succulent rhizome, from which arises several glaucous, jointed, solid stems, from an inch to two inches in diameter, from six to twelve feet high, and containing a white and juicy pith. The color of the stem is yellow, greenish yellow, purple, or striped. The joints are about three inches apart, and give origin to the leaves, which embrace the stem at their base. The leaves are three or four feet long and about an inch wide, flat, acuminate, longitudinally striated, furnished with a white midrib, glabrous, finely dentate, and of a green color inclining to yellow. The flowers are pinkish, surrounded by a long silky down, and disposed in a large, terminal, nearly pyramidal panicle, composed of subdivided spikes, and two or three feet in length. The plant has a general resemblance to Indian corn. Four varieties are mentioned: 1, the common, with a yellow stem; 2, the purple, with a purple stem and richer juice; 3, the gigantic, with a very large light-colored stem; and 4, the Otaheitan, which was introduced into the West Indies from the island of Tahiti (Otaheite) by Bougainville and Bligh, and is distinguished by its greater height, the longer intervals between its joints, and the greater length of the hairs which surround the flowers. Sugar cane was originally indigenous in all probability to India. It has been cultivated for its saccharine juice since remotest antiquity. At the present time it is cultivated in all tropical and sub-tropical countries. It was introduced into the West Indies by the Spaniards early in the 16th century, and these islands, especially Cuba, are now the world's largest producers.

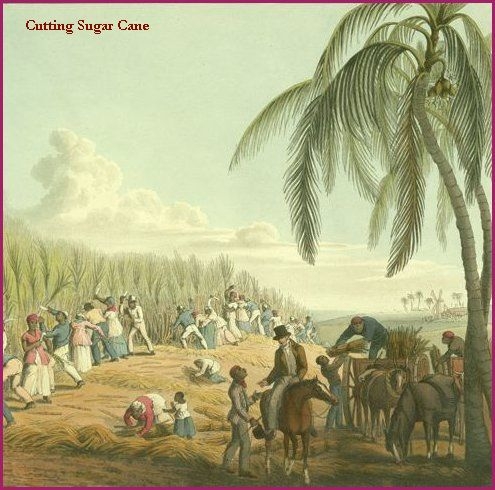

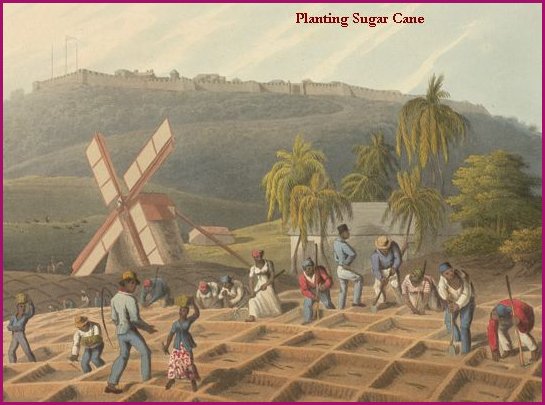

The sugar cane is cultivated by cuttings, which are planted in rows, and which, by giving rise to successive shoots, furnish five or six crops before the plants require to be removed. At the end of a year or more the plant flowers, but before this takes place the canes are richest in sugar and are cut down. The quantity of sugar which they yield is variable. According to Avequin of New Orleans, the proportion of cane sugar in the recent stalk is about 10 per cent.; of uncrystallizable sugar from 3% to 4 per cent. Cane juice is said to contain 17 per cent, of crystallizable sugar, though not more than 13 per cent, is extracted in practice.

The Sugar beet (Beta, vulgaris L.) is extensively grown in temperate zones as a source of sugar, or Saccharose. It is extensively grown in Europe and the western United States. The plant is a biennial resembling the ordinary garden beet. The varieties yielding sugar produce rather small tuberous roots, which are either yellowish or whitish internally. They yield 10 to 18 per cent, of sucrose, depending upon selection and cultivation.

Sucrose is also largely produced in Canada and the northern parts of the United States from the sap of the sugar maple (Acer saccharinum). This variety is never refined or purified as it owes its value as a confection and flavor to the impurities naturally present in the crude product. Cane sugar may be obtained from cornstalks, and from the Chinese sugar cane, or Sorghum saccharatum, which latter source for a time assumed some importance in Kansas and the Northwest. In India, sugar is made from the sap of different species of palm. Crude palm sugar is called jaggery.

Preparation and Purification.�The canes, when ripe, are cut down close to the earth, topped, and stripped of their leaves, and then crushed between a series of horizontally placed iron rollers in a mill, or they are cut in thin transverse slices and the juice extracted by diffusion with warm water. The juice, constituting 90 per cent, of the cane, though much less is actually obtained, is of a pale greenish color, sweet taste, and balsamic odor, and has a sp.gr. varying from 1.033 to 1.106. It usually contains from 15 to 20 per cent, of sucrose. As it runs out it is received in suitable vessels, and, being quickly removed, is immediately mixed with lime, in the form of milk of lime, in the proportion of about 1 part of the earth to 800 parts of the juice, and heated in a boiler to 60� C. The exact proportion of the lime cannot be determined, as the juice varies in quality in different seasons; but the manufacturer should aim at leaving the juice still slightly acid.

The albuminous matter rises to the top, and forms a thick scum, from underneath which the liquid is drawn off by a cock into a copper boiler, where it is concentrated by heat, the scum being carefully skimmed off as it forms. When sufficiently concentrated, the juice is transferred to shallow vessels called coolers, from which, when it assumes a granular aspect, it is drawn off into Wooden vessels with perforated bottoms, the holes in which are temporarily plugged. At the end of twenty-four hours the liquid is strongly agitated with wooden stirrers, in order to accelerate the granulation of the sugar, which is completed in six hours. The stoppers are now removed, and the syrup is allowed to drain off from the sugar.

The substance obtained by the evaporation of cane juice is known as brown sugar or muscovado; it is a yellowish, crystalline and somewhat moist substance, which is decolorized and purified to form granulated sugar. The syrup, by a new evaporation, furnishes an additional portion of sugar, and the liquid which finally remains, incapable of yielding more sugar with advantage, is called molasses. Sugar produced in this way is called "open pan" sugar. It is now almost completely displaced by "vacuum pan " sugar.

In the production of raw sugars by the vacuum pan process, the juice, after "defecation" with lime and removal of excess of lime by carbonic acid gas, is run through large filters of bone black, and then into a vacuum pan for concentration. The vacuum pan is a large evaporating pan, closed above by a dome-like top, which connects with an exhausting steam pump, so that the liquid can be concentrated under a very reduced pressure. The heat is supplied by coils of steam pipes which run through the interior of the pan. The saccharine juice is evaporated in this until it begins to crystallize, and even after this fresh portions are added, so that the crystals already formed grow by accretion of fresh material. After the crystallization is complete, the warm mixture of crystals and syrup is run into "centrifugals," to which a rapid motion of revolution is given, and the crystals so drained and dried.

There is no doubt that a large proportion of the sugar is lost in the ordinary process of manufacture. Nearly 20 per cent is lost in even the most efficient of the processes. Melsens, of Brussels, proposed a process, which consists in the use of calcium bisulphite. This salt is alleged to act as an antiseptic, preventing the operation of any ferment; as an absorber of oxygen, opposing the action of that gas on the juice; as a clarifier, rendering insoluble at 100� C. all coagulable matters; as a bleacher of pre-existing coloring matters, and a preventative of the formation of new ones; and, lastly, as a substance furnishing a base to neutralize hurtful acids, which, unite with the lime, displacing the weaker sulphurous acid. This process is now largely used, and calcium bisulphite is used in British Guiana and other sugar-producing countries in immense quantities. Emil Pfeiffer proposed another refining process, which consists in the use of acid calcium phosphate, an agent previously recommended by Brande. Reynoso considered alumina the best defecating agent, having succeeded by means of it in throwing down almost all impurities most hurtful. He adds the acid aluminum phosphate to the cane juice, and decomposes this with lime, by which the calcium phosphate is produced and alumina separated, and all these, with some lime in excess, cause the elimination of coloring and nitrogenous matters, so that there remain in the liquid only some of the salts which normally accompany the sugar in the juice.

The refining of raw sugar forms a distinct branch of business, and the methods pursued have undergone many improvements. The sugar which contains from 88 to 90 per cent, of sucrose is first " melted " that is, dissolved in hot water and then sometimes clarified by heating it with bullock's blood, although sulphites, phosphates, and other defecating agents referred to in preceding processes may be used. The clarified syrup is then strained through cloth filters, whereby it is rendered limpid. The clear straw colored syrup from the bag filters is then run into the char filters�that is, large percolators filled with freshly ignited bone black. In sugar refineries these are 25 or 30 feet in height and sometimes hold several thousand pounds of bone black each and some refineries have dozens of such units. The bone black may be reactivated several times by heating and is finally discarded and sold for fertilizing purposes. A bleaching compound known as blankit (sodium hydrosulphite) is sometimes used to spare the use of bone black filters.

The syrup after filtration goes to the vacuum pans. By reduced pressure the syrup is made to boil at a lower temperature, and with a diminished contact of the air, and the loss of cane sugar by change into that which was uncrystallizable is in great measure avoided. Two, three, or even four vacuum pans may be coupled together so as to economize fuel, and the vapors arising from one made to heat the next, in which a more perfect vacuum exists, allowing of evaporation at still lower temperatures. Such a combination is called a double, triple, or quadruple effect apparatus.

At one time it was the custom to discontinue the decolorization process before an entirely white sugar was obtained, and then to add a small amount of ultramarine blue to overcome the yellow appearance of the granulated sugar. This process has practically been abandoned within recent years. The syrups of lowest quality are employed in forming inferior white sugar, from which syrup finally drains containing so little cane sugar as not to repay the expense of extracting it. This constitutes sugar-house molasses. Good brown sugar, in the process of refining, yields over 75 or 80 per cent, of white sugar. A comprehensive historical article by C. A. Browne, on the development of the sugar industry is found in the A.J.P., 1915, p. 10.

Commercial History. Cane sugar was known to the ancients. It was originally obtained from India, where it was extracted from the sugar cane. About the period of the Crusades, the Venetians brought it to Europe; but at that time it was so scarce and costly as to be used exclusively as a medicine. Upon the discovery of the Cape of Good Hope and the maritime route to the East Indies, the commerce in sugar passed into the hands of the Portuguese. Subsequently the cultivation of the cane extended to Arabia, Egypt, Sicily, .Spain, and the Canaries, and finally, upon the discovery of the New World, to America, where it was pursued with the greatest success, and continues to be so. In America it was produced most abundantly in the West Indies, which supplies also a part of the consumption of Europe. The Cuban production has grown rapidly in recent years, and is now over 3,000,000 tons annually. About an equal quantity is produced in Germany from beets. Considerable beet-sugar is also produced in the United States.

Classification of the Carbohydrates.�The term "sugars" is applied to a large number of carbohydrates. Emil Fischer has not only made numerous syntheses in this group, but has greatly widened our knowledge of the relations of the several sugars, permitting a more comprehensive classification than formerly. While no sugars are found in nature containing less than six atoms of carbon, synthetic compounds are formed belonging in the first, or monosaccharide, class which contain three, four, and five atoms of carbon, as well as others containing seven, eight, and nine atoms of carbon. The nomenclature of the sugars is based upon the fact that simple sugar molecules are distinguished by the Greek prefixes tri, tetra, penta, etc., indicating the number of carbon atoms in the molecule; thus, glycerose, C3H6O3, is a triose, while dextrose, C6H12O6, is a hexose. These are called monosaccharoses, monosaccharides or monoses. These simple sugar molecules are taken as the basis for a secondary classification based upon the number of monoses or simple sugar molecules represented in the molecular structure of the more complex members of the group. The Greek numerical prefixes are also used to distinguish these; thus, dextrose, C6H12O6, is a monosaccharide, while sucrose, C12H22O11, is a disaccharide produced by the union of two monosaccharide molecules with the elimination of water. Of the simple sugars, members ranging from three to nine carbon atoms are known (trioses to nonoses), while of the broader groupings, monoses, dioses, trioses, monosaccharides, etc.), contain respectively one, two, or three of the simple sugar molecules, while polyoses or polysaccharides contain an indefinite or larger number of monoses. The glucosides are substances closely related to the carbohydrates. They are of frequent occurrence in plant tissues and are characterized by the fact that when heated with dilute acids or dilute alkalies or subjected to the action of certain enzymes, they decompose into a glucose and an alcohol, phenol, aldehyde or nitrogen compound; hence they are probably ethers or ethereal derivatives of the monoses. (See Amygdalin, Salicin, etc.) Artificial glucosides have been prepared by Fischer (B. Chem. G 1893) by the interaction of a monose and an alcohol in the presence of a dehydrating agent. Glucosides contain only carbon, hydrogen and oxygen except in the case of the cyanogenetic glucosides such as amygdaline, in which the nitrogen splits off as hydrocyanic acid. Sucrose, in a pure state, is a solid of a peculiar grateful taste, permanent in the air, phosphorescent by friction, and of the sp. gr. 1.6.

Description and Physical Properties � White hard, dry crystals or blocks, or a white, crystalline powder. It is odorless, has a sweet taste, and is stable in the air. One Gm. of Sucrose is soluble in 0.5 cc. of water and in 170 cc. of alcohol, at 25� C. One Gm. is soluble in slightly more than 0.2 cc. of boiling water. It is insoluble in chloroform and in ether.

The specific rotation of Sucrose determined at 20� C. in an aqueous solution containing in each 100 cc. 26 Gm. of Sucrose, previously dried to constant weight at 105� C., and using a 200 mm. tube, is not less than + 65.9�.

An aqueous solution of Sucrose (1 in 20) is neutral to litmus paper.

Ash: not more than 0.05 per cent. An aqueous solution of Sucrose (1 in 1) is colorless or at most only faintly yellow when viewed horizontally against a white background through a vertical cylinder of colorless glass having an inside diameter of about 25 mm.

When kept in large, well-closed, and completely filled bottles, the solution deposits no sediment on prolonged standing (insoluble salts, ultramarine or Prussian blue). Its aqueous solution (1 in 10) is not affected by the addition of an equal volume of hydrogen sulphide T.S. (heavy metals). Ten cc. portions of the solution (1 in 10), remain clear for at least one minute after the addition of 1 cc. of silver nitrate T.S. (chloride) or of ammonium oxalate T.S. (calcium). A 5 Gm. portion of Sucrose shows no more sulphate than corresponds to 0.3 cc. of fiftieth normal sulphuric acid. Dissolve 20 Gm. of Sucrose in enough distilled water to make 100 cc. and filter the solution if necessary. To 50 cc. of clear liquid contained in a 250 cc. beaker, add 50 cc. of alkaline cupric tartrate solution, heat the mixture at such a rate that approximately four minutes are required to bring it to the boiling point, and boil for exactly two minutes. Add 100 cc. of cold, recently boiled distilled water, and collect and weigh the precipitated cuprous oxide in the following manner: Prepare a Gooch crucible with an asbestos layer. Thoroughly wash the asbestos with distilled water, followed successively by 10 cc. of alcohol and 10 cc. of ether, dry at 100� C. for thirty minutes, and weigh the prepared crucible. Filter the precipitated cuprous oxide through the crucible thus prepared, thoroughly wash the residue on the filter with hot distilled water, then with 10 cc. of alcohol, and finally with 10 cc of ether, and dry it at 100� C. The weight of the cuprous oxide does not exceed 0.155 Gm., corresponding to not more than 0.5 per cent, of invert sugar." U.S.

Colorless and inodorous crystals, or in crystalline masses. Readily and completely soluble in half its weight of water, forming a clear, colorless and odorless syrup which does not develop an unpleasant odor when acidified with hypo phosphorous acid and allowed to stand for twenty-four hours; the syrup, heated to about 82� C. with solution of potassio-cuprio tartrate, does not yield more than a trace of a red or yellow precipitate (absence of glucose). Yields no reactions for barium, strontium, calcium, chlorides or sulphates. Ash not more than 0.05 per cent." Br.

Its solution, when thick and strong, is called syrup; when alcohol is mixed with this the sugar is gradually deposited in crystals. An aqueous solution of sugar, kept in a warm place, has the property of corroding iron, partially immersed in it, just above the line where the surface of the liquid touches the metal, and the solution itself becomes impregnated with ferrous oxide, and of a deep red-brown color. A similar effect is produced on lead, but zinc and copper are but slightly acted on. A solution of sugar possesses the property also of dissolving a large quantity of calcium hydroxide, forming a compound called calcium saccharate. When concentrated syrup is gently heated, and spirit added to it, the liquid, on cooling, forms white semi-transparent crystals of hydrated sugar, having the shape of oblique, four-sided prisms, and called rock candy. This is the purest form of sucrose commercially obtainable. When heated to 185� C., it melts into a viscid, colorless liquid, which on being suddenly cooled forms a transparent mass, called barley sugar. At a higher temperature, between 204.4� and 215.5� C., it loses two molecules of water, and is converted into a black syrupy liquid which is official in the N. F. as Caramel. At a still higher temperature it yields combustible gases, carbon dioxide, empyreumatic oil, and acetic acid, and there remains about one-fourth of its weight of charcoal, which burns without residue.

Sugar renders the fixed and volatile oils to a certain extent miscible with water, which is probably a colloidal suspension; such mixtures are called oleosaccharures. When in solution, it is not precipitated by lead sub acetate, a negative property which distinguishes it from most other organic principles.

Cane sugar may be distinguished from grape sugar by the fact that it does not reduce alkaline copper tartrate (see official tests), nor basic bismuth nitrate. See the official test above.

Action of Acids and Alkalies.�The mineral acids act differently on cane sugar according as they are concentrated or dilute. Strong nitric acid, with the assistance of heat, converts it into oxalic acid. The same acid, when weak, converts it into saccharic acid, (CHOH)4(COOH)2, confounded by Scheele with malic acid. Concentrated sulphuric acid chars it. Diluted hydrochloric acid, when boiled with cane sugar, converts it into a solid, brown, gelatinous mass. Weak sulphuric acid, by a prolonged action at a high temperature, converts cane sugar, first into uncrystallizable invert sugar, afterwards into grape sugar, and finally into ulmin and ulmic acid. The inversion of cane sugar by dilute acids is one of the most characteristic phenomena and is utilized in its quantitative estimation and is a factor in the changes which take place in many pharmaceutical preparations. It is called inversion because the sugar before the change takes place is dextrorotatory while after the operation it is levorotatory. The reaction is as follows:

C12H22O11 + H2O = C6H12O6

+ C6H12O6

Sucrose

Dextrose Laevulose

The reason

for the laevorotatory power is that laevulose is more

strongly laevorotatory than dextrose which is dextrorotatory. The amount of

acid that will produce the change is very small indeed. One drop of

hydrochloric acid will invert 1 Ib. of sucrose in a few minutes at the

optimum inversion temperature which is 80� C.

The reason

for the laevorotatory power is that laevulose is more

strongly laevorotatory than dextrose which is dextrorotatory. The amount of

acid that will produce the change is very small indeed. One drop of

hydrochloric acid will invert 1 Ib. of sucrose in a few minutes at the

optimum inversion temperature which is 80� C.

Commercial invert sugar which is used in food products and sometimes as an adulterant of honey is usually prepared by the use of citric acid as an inversion medium, four ounces of citric acid being sufficient for 500 Ibs. of sucrose. The sucrose of course must be in solution, the best density being about 1.3

Invert sugar is sweeter than sucrose and is the cause of the cloying sweetness of some syrups and preserves in which inversion has been produced by the natural acidity of the constituents. Cane sugar unites with the alkalies and some of the alkaline earths, forming definite combinations which render the sugar less liable to change. It also unites with lead monoxide. Boiled for a long time with aqueous solutions of potassium hydroxide, the liquid becomes brown, formic acid is produced, and two new acids are generated, one brown or black and insoluble in water, called melassic acid, the other colorless and very soluble, named glucic acid. Alkalies and the alkaline earths are said to lessen the rotatory power of sugar in relation to polarized light, but the sugar recovers its power when the alkali is saturated. (J.P.C., 4e ser., iv, 314.) The action of acids and alkalies on cane sugar explains the way in which lime acts in the manufacture and refining of sugar. The acids naturally existing in the saccharine juice have the effect of converting the cane sugar into invert sugar, by which a loss of the sucrose is sustained. The lime, by neutralizing these acids, prevents this change. An excess of lime, however, must be carefully avoided, as it injures the product of cane sugar in both quantity and quality. The, change in sugar which precedes fermentation, namely, the conversion of sucrose into the uncrystallizable invert sugar, points to the necessity of operating on the juice before that process sets in, and hence the advantage of grinding canes immediately after they are cut, and boiling the juice at once.

Molasses, sometimes Latinized in prescriptions as Syrupus Fuscus, is of two kinds, the West India and sugar-house. West India molasses is a black thick liquid, of a peculiar odor and sweet empyreumatic taste. When mixed with water and with the skimmings of the vessels used in the manufacture of sugar, it forms a liquor which, when fermented and distilled, yields rum. Sugar-house molasses, golden drips, or grocer's syrup is thicker than the West India molasses, and has a different flavor; as found in commerce, it is sometimes adulterated with glucose. Its sp.gr. is about 1.4 and it contains about 75 per cent, of solid matter. Both kinds of molasses contain uncrystallizable sugar, more or less cane sugar which has escaped separation in the process of manufacture or refining, and gummy and coloring matter. New Orleans molasses was formerly the most largely used variety, but has practically disappeared from the market, owing to the changed conditions of manufacture.

Uses.� Although sugar is so important a foodstuff today, it does not seem to have been widely employed in Europe until the tenth or eleventh century. It was known much earlier to the European writers, such as Dioscorides, who lived in the first century, by whom it seems to have been regarded as a sort of natural curiosity. Its food value is very high, commercial cane sugar yielding more than 4 calories of energy per gramme. It is not, however, directly utilizable by the body cells, but must first be inverted into dextrose or laevulose; this is true also of the other disaccharides such as lactose and maltose. The latter, however, do not hydrolize in the same way; lactose yields both dextrose and laevulose, maltose only dextrose.

This inversion is accomplished in the system probably in part by the hydrochloric acid of the gastric juice, but chiefly by a specific ferment which is found throughout the whole small intestines. It occurs with great rapidity so that the body can derive energy from ingested cane sugar almost as rapidly as it can be absorbed. So rapidly, indeed, is sugar absorbed from the intestinal tract that eating large quantities of it may overwhelm the ability of the liver to withdraw the sugar from the blood and lead to hyperglycemia and the appearance of glucose in the urine; a condition which is known as alimentary glyeosuria. Glucose and laevulose are directly assimilable and the body can derive nourishment from them even when injected hypodermically or intravenously.

Sugar is much used for the purposes of preserving organic substances. It is probable that it acts by producing rapid exosmose of the fluids of the fermentative organisms, its diluted solution being in fact prone itself to undergo fermentative change. All the different kinds of sugar susceptible of the alcoholic fermentation have this power. In pharmacy, sugar is employed to render oils miscible with water, to cover the taste of medicines, to give pharmaceutical preparations consistency, to preserve them from change, and to protect certain ferruginous preparations from oxidation. Accordingly, it enters into the composition of several mixtures, pills, and powders, of syrups and confections, and of all the troches. Molasses is used as an excipient for pills, and on account of its hygroscopic properties it prevents hardening