Herbs

in Africa.

Extraction Products

The Library Based Herbal Business

Part 6

Part~1

Part~2

Part~3

Part~4

Part~5

By

Ivor Hughes

In the

first 5 articles of this series of Herbs in Africa, we have looked in broad

outline at the basic requirements for small scale operations up to 4 ha in

size. So in the next few articles we will look at micro scale operations.

Herbs as a domestic industry. The micro production may be easily

scaled up to meet small scale operations

I have noted that in Europe, USA and the Southern hemisphere many such

enterprises have grown to the scale of small industry, whilst others have

met the requirements of a local market being quite happy to make an

independent living. Their offerings run the whole spectrum, edibles,

medicinals, but most important from a cottage industry perspective,

the body care and cosmetic market.

One may start by making small batches and circulating them in amongst

family, friends and colleagues. This would be your first marketing

exercise, this to judge likely public reaction to your products. If

they are good, then one could distribute by direct sale, mail order or

act as manufacturing wholesaler and persuade retailers to stock the

products. You will need to cost the products out. That means

everything involved in the selling price of the item must be carefully

worked out.

The basic raw material is the herbs. From article 1 in this series we have

the following information as representing fair average yields per ha but

only if the crops are at the correct spacing. That information is

available via the internet from the agriculture department of most

countries. For sound reasons one should always operate on dried herb.

Therefore the average dried yield figures will translate into,

Root : 2.5kg per m3. Herb : 2kg per m3 Flower Petals : 50g per m3

| Plant Part | Fresh Yield per ha. | Drying Ratio | Average Dry Yield |

| Root | 7500 kg | 3:1 | 2500 kg |

| Herb | 8000 kg | 4:1 | 2000 kg |

| Flower | 5000 kg | 10:1 | 500 kg |

One square metre is not a large space and may be converted into boxes or containers to grow the herbs in. Container and patio gardening is popular on a global basis. Much valuable information may again be gleaned from the internet with reference to what is required for that type of production.

The root and herb in the majority of cases will be the substances that are included in the majority of the actives used in the products. There are some preparations in which whole dried flowers are extracted, but the general rule is, that petals are used to perfume a product. Accordingly the ratio of perfume to product is very small in comparison to the bulk of the product.

The amount of actives in a product would be at a strength of :

(1) 1:10 ... 10 ml is equal to 1g of the air dried plant. 1kg is the

equivalent of 10 litres.

(2) 1:20 ... 20 ml is equal to 1g of the air dried plant. 1kg is the

equivalent of 20 litres

(3) In Homeopathic potencies.

In practice the starting extraction rate would be 1:1 (1kg = 1litre) if it

is to be incorporated in a lotion, cream or salve. If your intended

product were a potion then the 1:10 and 1:20 figures will give you an

estimate of end product yield.

Essential

Apparatus.

Much of the apparatus required for the manipulation of plant material may be

found in any reasonably well equipped kitchen.

Heat and

oven proof glass ware. Weighing scales which should be accurate to 1g.

Temperature controlled cook pots and fry pans. The fry pan makes a very good

water bath for temperature control purposes. Coffee grinder and Blender will

be found most useful for size reduction of the raw botanic material.

Try to ensure that all materials in contact with the solvent is either

glass or stainless steel.

If you intend to sell your products, then the minimum standard of hygiene,

is that which is expected of a restaurant kitchen.

The

Solvents.

The solvents are

(1) Distilled water.

(2)

Rectified spirit 90%

v/v. (3)

Various

strengths of alcohol and water. There are some very sound reasons for

this. One may obtain the ethanol either by the fermentation and

distillation of ones own spirit. Rectify wine or rectify commercial spirits.

(See part 3 of this series) One may purchase laboratory glass ware which is

expensive or use your ingenuity and make your own apparatus.

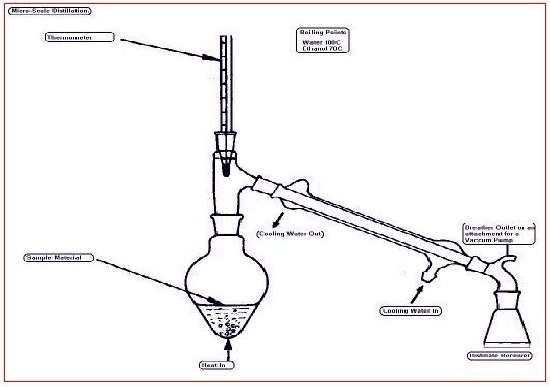

Distillation Apparatus.

Commercial Glasswarewith ground glass joints.

The glassware has many advantages. It may be easily stripped for cleaning

purposes.

It is light

and portable and conducts heat efficiently. Major draw backs are that

it is fragile, expensive and only suitable for small batches.

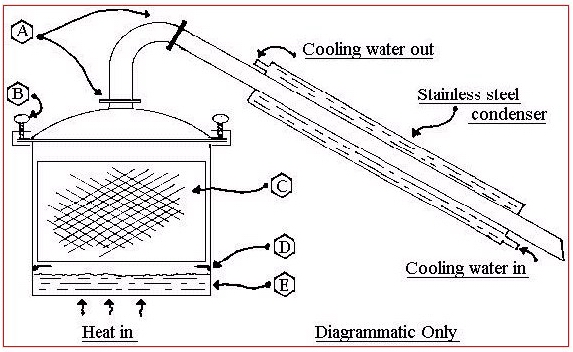

Home Made Apparatus.

The Key :

(A)

Breakable joints

for cleaning purposes.

(B) 'G' clamps to secure the still

head to the body of the still.

(C) Stainless steel frying basket.

with the handle bent across the mouth of the basket

(D) Welded lugs to support the

basket.

(E) Liquid reservoir.

The apparatus as shown is a modified stainless steel pressure cooker. In its

current configuration it is used for the extraction of essential oils for

small scale use. Oils are obtained by steam passing through the

material in the charge basket.

If the basket is removed it may be used to manufacture or rectify alcohol.

With a suitable modification the apparatus may be used with a venturi tube

for distillation under reduced pressure. The apparatus is simple, robust,

and relatively cheap to make.

Two construction points of importance

(1) The still head and still body must have a hermetic seal.

(2) The Condenser must be sized to dissipate the heat generated and

efficiently condense the vapours back to liquid. These two points are

usually the cause of failure or inefficiency in home built apparatus.

High Strength Alcohol By Freezing Out :

This is an ancient technique that preceded that of distillation, and was

known to the central Asian tribes 500 years before the birth of Christ.

Empty a bottle of wine or spirits into a suitable sealed container. Water

when it turns to ice will expand, so ensure that there is sufficient

expansion room in the container. Place the container into the domestic

freezer and leave until the water has frozen.

The unfrozen liquid is high strength alcohol. Decant it and seal it in a

glass bottle. It is volatile i.e. it is inflammable and will evaporate

easily.Freezing

Point: -114.00 deg C. Boiling Point: 78.00 deg C.

This method was first bought to the attention of Europeans by Paracelsus in

his published work

'Archidoxis' written in 1527. Francis Bacon

reported as follows ;

"Paracelsus reporteth, that if a glass of wine be set

upon a terrace in bitter frost, it will leave some liquor

unfrozen in the centre of the glass, which excelleth

Spiritus Vini drawn by fire.

The basic

extraction apparatus in which you will use the solvents is shown in

Part 5 of this series.

Raw

Materials :

The production of salves, creams and lotions will require some or all of the

following which are used as the carriers for the active substances :

(a)

Beeswax (preferably unbleached)

(b) Good

quality sweet almond or sunflower oil. (It should have been deodorised

)

(c) Gum Benzoin (As a preservative)

(d) Honey and Propolis

This theme will be further explored in coming articles. Further information

may be found on this web site.

N.B. I

have had feedback that there appears to be a problem with the freezing out

of ethenol from cheap chateau cardboard wine and also from a brandy

manufactured in the USA which the label stated was 40 % by volume.

The brandy turned into a syrupy mass whilst the cheap wine just froze ike a

block of ice. The freezing point between alcohol and water is big enough to

drive a railway engine through.

The only logical explanation is that both of the liquids contain additives

which have bound the ethanol to the water in such a way that they cannot be

separated by freezing. I know from personal experience that a wide range of

chemicals including glycerine is added to improve taste in inferior wines.

If glycerine is present in any quantity it will alter the physical

characteristics of the liquid. In that situation the only resort is to

distillation.

Distillation cannot produce absolute alcohol. Maximum is 95 % by volume. The

remaining 5 % water has to be removed by chemical means.

Another possible explanation is that the ethanol contained is not from an

accepted plant source. For example it could be produced from milk whey, or

even wood chips. To the chemist alcohol is alcohol and is given the same

chemical formula.

I believe this to be incorrect. The physiological effects of alcohol

produced from fruits, grains and other plant parts differ from each other in

their effect on the mental state. However, as a body they have a

totally different effect to that of alcohol produced by synthesis, rather

than by fermentation.

Ivor

Hughes

Library

Part~1

Part~2

Part~3

Part~4

Part~5

The Pharmageddon Herbal

The

equivalent of a 3 year certificated course in Western Herbology, Save

yourself thousands.

These articles have been published in

Science In Africa

www.scienceinafrica.co.za

![]()